In order to ensure long-term stable operation of the product in actual engineering, the following factors have an important impact on the service life of armor rods:

1. Material selection and anti-corrosion performance:

Armor rod material types: Aluminum-clad steel has excellent corrosion resistance and strength, galvanized steel is economical and practical, and high-strength alloys are suitable for heavy loads and various environments.

Armor rod surface treatment: Anti-corrosion coating and smooth surface treatment can reduce wear and extend service life.

2. Installation quality:

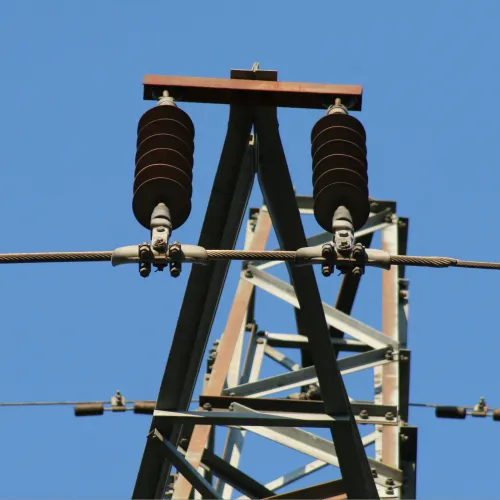

Correct installation of armor rods: Whether the twisting direction, coating length and wire matching are reasonable affects the stress distribution and fatigue resistance.

Tools and construction techniques: Although armor rods can be installed without tools, professional operation can ensure a more stable contact effect and prevent wire damage.

3. Use environment:

Climate impact: high humidity, high salt fog, acid rain and extreme temperature difference environment will accelerate metal corrosion and aging.

Mechanical load: wind vibration, icing, earthquake, etc. will produce periodic stress. If there is no shock-absorbing accessories used, it will affect the service life of armor rods.

4. Wire matching and tension:

Tension compatibility: The wire tension should be within the design range of the armor wire. Overload may cause slippage or breakage.

Precise model matching: Armor rods should be customized according to the type of wire (such as ACSR, AAAC, OPGW, etc.) to ensure a firm fit.

5. Operation and maintenance inspection:

Regular inspection: Check whether the armor rods are loose, corroded, deformed, etc., which helps to find problems early.

Timely maintenance: Replace the armor rods or reinforce them in time when problems are found to avoid damage to the wires or accessories.

Vilun's armor rods product advantages:

Multi-level mechanical protection, effectively reducing wire fatigue;

Simple module design, easy installation of armor rods, reducing construction and material costs;

Armor rods have excellent weather resistance and corrosion resistance, adapting to a variety of environments;

High reliability engineering applications, armor rods have been widely used in many international projects.

As a high-tech enterprise from Changchun, we have been focusing on the manufacturing of spiral hardware for many years., Vilun has always adhered to the production concept of dddhhhquality firstdddhhh. With large-scale manufacturing capabilities, perfect export processes, strict quality inspection standards and fast technical support, we have become a trusted partner for many overseas customers.

Welcome to contact us for quotes or technical information, let us work together to provide reliable protection solutions for global power transmission lines!